INDUSTRIAL GAS SUPPLY, TECHNOLOGY & EQUIPMENT FOR METAL PRODUCTION

Strengthening Your Process

We are the leading provider of gas for metals production. POL’s manufactured gases are commonly used in the manufacture of metals for minimal costs, improved energy efficiency, environmental advantages and productivity.

However, our ties with our consumers are much deeper than consumer products. We deliver a broad range of services including technology, installation of storage tanks, start-up and assistance. From cylinders and on-site systems, and centralized manufacturing plants, we offer solutions that work for your business as you get all your products from one industrial gas supplier.

See how we serve related industries.

INDUSTRIAL APPLICATIONS FOR THE METAL PRODUCTION INDUSTRY

Argon Oxygen Decarburization (AOD)

Over 75% of the world’s steel is made with our Argon Oxygen Decarburization (AOD) process. Lower your material costs, produce cleaner metals and increase productivity with AOD.

Direct Oxygen Injection

Used in foundries, mini-mills and stainless steel mills, direct injection processes lower costs and improve furnace productivity, when used with right systems.

Oxygen Enhanced Combustion

POL supplied oxygen, when used with right combustion system, helps convert your furnace air-fuel burners into oxy-fuel burners. This may increase your productivity and help decrease fuel consumption.

Hot Oxygen Technology

POL supplied oxygen, when used with right technology, rapidly burns hard to combust materials and easily preheats oxygen to high temperatures at point of use, to give you the best possible results.

Stove Oxygen Enrichment

POL supplied oxygen, when used with right system, can help you reduce or potentially eliminate the need for fuels like coke oven gas and natural gas while generating higher blast temperatures.

Inerting

With the right technology you can reduce alloy oxidation, slag formation, and dissolved oxygen, nitrogen, and hydrogen in metals to produce better fluidity and easier casting.

Heat Treating

With the use of nitrogen and hydrogen-based combustion system you may lower the cost, improve productivity, and may help precisely meet specifications.

Aluminum Die Cooling

Nitrogen-based cooling can help with temperature control in aluminum extrusion. It is an important step in producing quality products and maximizing productivity potential.

Aluminum Melting

With POL supplied gases and the right equipment for aluminum melting may help you achieve higher production output in your furnace operations while providing energy savings and lowering your NOx emissions.

Aluminum Dross Cooling

With POL supplied gases and the right equipment for aluminum dross cooling can help you develop your aluminum recovery process and increase your aluminum recovery rate.

Mining

We supply gases for mine inerting, flotation, leaching, roasting, pressure oxidation, carbonate precipitation, and pH control and water treatment.

Sub-Zero Parts Freezing

Heat treated metal is often cooled before the next step. With POL supplied liquid nitrogen your freezers may optimizes the micro-structure to achieve more desirable properties like increased strength and durability.

OPTIVIEW™ Image Analysis System

The OPTIVIEW Image Analysis System uses flame image technology to enhance combustion control and reduce emissions. This innovation enables real-time, automatic control of the energy into the melting process.

OPTIFIRE™ Fluidic Burner

The OPTIFIRE fluidic burner shas features that may help increase energy efficiency and productivity. A remote-controlled operation allows the flame to be directed at cold scrap and accelerates the meltdown in the furnace. The flame can be programmed to move on horizontal and vertical planes.

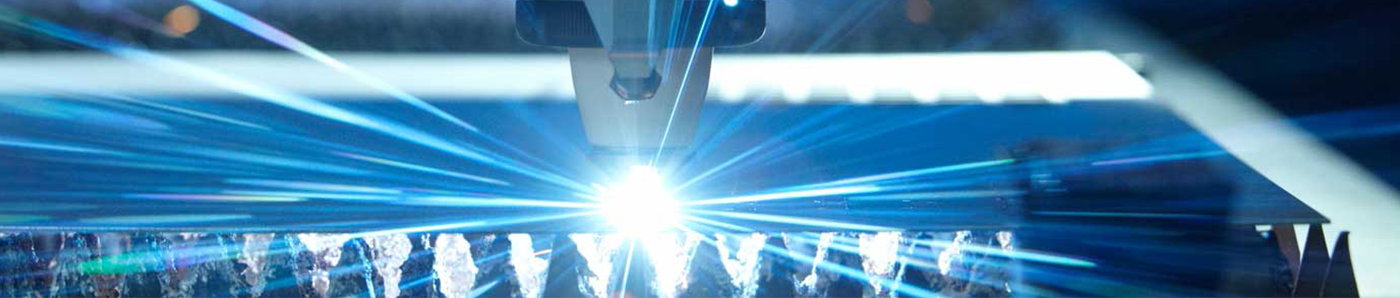

COJET® Gas Injection System

The COJET Gas Injection System uses a process and injector nozzle that delivers a laser-like coherent jet of oxygen at supersonic speeds. It also allows for automatic furnace operation, decreases metal production costs through lower power consumption, and more.

OPTIFIRE™ JL Burner

The OPTIFIRE™ JL Burner is designed to provide savings and improved production by increasing the melting rate with more cycles per day. This burner is best to use for applications that only use oxy-fuel.

OPTIFIRE™ Hybrid Burner

The OPTIFIRE™ Hybrid Burner allows flexible use of air and oxygen. It can be operated with oxy-fuel combustion when high melting rates are needed and with air during the holding and alloying phases.

INDUSTRIAL SERVICES FOR THE METAL PRODUCTION INDUSTRY

Our teams of engineers and market specialists work with customers to understand their business needs and their existing processes to develop the relevant solutions that are tailored specifically to their requirements. Please contact us for the most cost effective services for your business.